FIND A CONTACTOR

We want to hear about your Terrazzo Floor project. Give us a few details and a contractor will contact you shortly.

TERRAZZO FLOORING INSTALLER IN Burbank

OUR PURPOSE

The Terrazzo Network is an independent online resource dedicated to the art and science and education of terrazzo flooring. The Terrazzo Network’s mission is to educate Architects, Designers, Contractors, Facility Owners and Homeowners in Burbank on the most current and unbiased information regarding the design, installation, and care of terrazzo floors.

YOUR ONLINE RESOURCE CENTER

Nearly all of the information on terrazzo floors found on the internet is found on the proprietary websites of material suppliers, contractors, and contractor member trade associations. The Terrazzo Network of Burbank offers the most complete independent online resource for information about terrazzo flooring, installation and design, including technical information, photographs, a directory of terrazzo installers and product suppliers.

The terrazzo network can be used as an educational tool; as well as the starting point of bringing together technology and skilled craftsmen to create the artist’s vision in the form of terrazzo flooring.

Residential Projects

Frequently Asked Questions

Terrazzo is simple to maintain. Requiring occasional sweeping, mopping, and buffing.

Periodic resealing of a terrazzo floor is recommended to maintain a better looking floor.

Components of Terrazzo

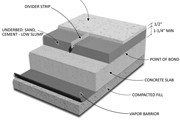

Terrazzo divider strips play an important role in the finish of terrazzo. They are used for joints to help control cracking, for pouring by helping maintaining consistent thicknesses, designs, dividing colors and patterns. They come in all shapes and sizes and are made from metals or plastic.

PROCESS & LAYERS

Terrazzo craftsmen create walls, floors, patios, and panels by exposing marble chips and other fine aggregates on the surface of finished concrete or epoxy-resin.

Traditional cement terrazzo is installed over a solid, level concrete foundation that is three to four inches deep. After the forms are removed from the foundation, a one-inch layer of sandy concrete is added.

Before this layer sets, terrazzo workers partially embed metal divider strips in the concrete wherever there is to be a joint or change of color in the terrazzo. For the final layer, terrazzo workers blend and place into each of the panels a fine marble chip mixture that may be color-pigmented.

TERRAZZO FLOOR DURABILITY

Polyacrylate based terrazzo is U.V stable and can be installed to the exterior as well as the interior. Any aggregate like marble blends, mother of pearl blends which is abalone crushed shells, recycled aggregates like glass, porcelain, concrete, and metal can be used in both terrazzo types.

Also shapes and medallions can be fabricated on site by bending divider strips, or sent out to be cut by water jet. When the terrazzo is dry, it can be ground it with various grinders, also referred as floor grinder/polishers.

Voids left by the grinding are filled with a matching grout material and hand-troweled for a smooth, uniform surface; it is then cleaned, polished, and sealed.